Introduction:

Business organizations exist to make a profit out of their business. If there is no profit, then there is no meaning in running a business. Supply Chain Management (SCM)’s main objective is to create a profitable SCM. The higher the SCM profitability, the more successful the SCM is.

In current work, to be competitive and profitable in the market most organizations focus on their SCM improvements. Else it can be a significant roadblock for their growth.

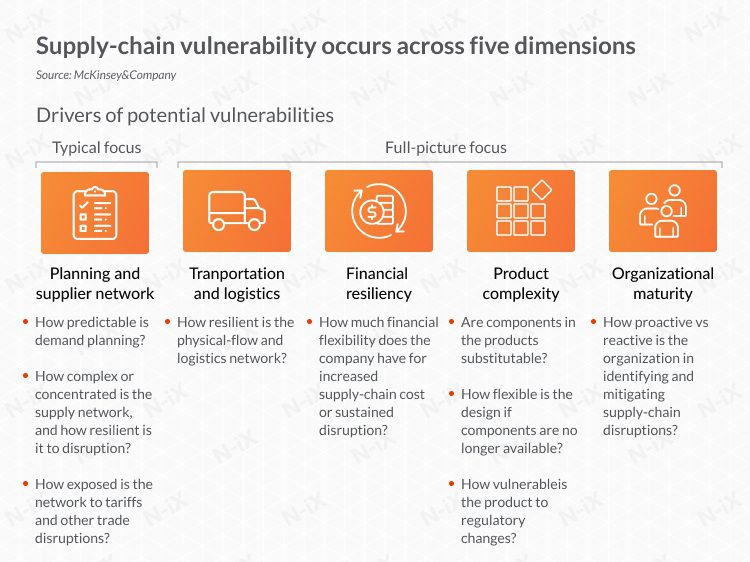

According to McKinsey, there are 5 major sources of vulnerability in the supply chain caused by the pandemic. And machine learning use cases in the supply chain serve as a ready-made blueprint of activities regarding what supply chain professionals should begin with in order to solve major supply chain issues.

AI/ML can take a major role in SCM in different stages. In this article we will see the followings:

- The expected job of AI in SCM,

- Necessary algorithms, tools and frameworks,

- Two contextual analyses of renowned organisations involving AI in SCM

Benefits and expectations of AI/ML in SCM:

SCM has become data serious. Nowadays all the data is gathered and put away in cloud databases and the need of distribution centres, and transportation hardware can be subbed.

Data is accessible in gigantic sums. Experts know how significant it is for SCM, and with the assistance of AI they can take advantage of it, think of a streamlined arrangement and fabricate devices that can assist them with pursuing better decisions.

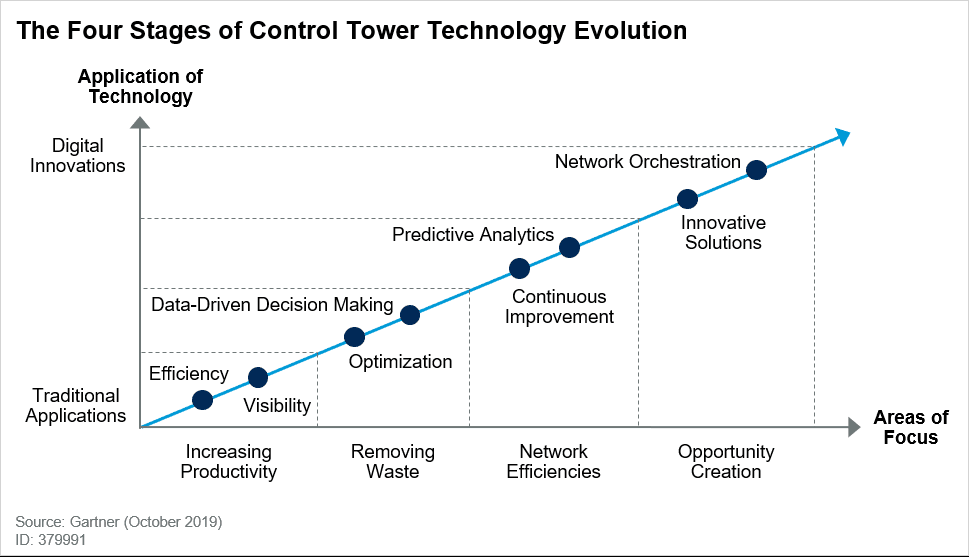

Control tower is at this point not simply a popular expression in that frame of mind of coordinated operations and supply chains. Today a basic arrangement is continually going through consistent development regarding innovation and its extent of work in the SC space.

Gartner’s meaning of a control tower is an idea that joins individuals with cycle and association, worked with by fittingly consolidated innovation for giving information-driven, start-to-finish supply chain bits of knowledge.

In basic terms, Control towers are a fruitful blend of the physical and digitalized supply chains to acquire worked on start to finish perceivability and control over every one of the elements of the supply chain. They are the single window to cutting-edge investigation and direction, framed based on human and machine knowledge. AI/ML can take a major role here.

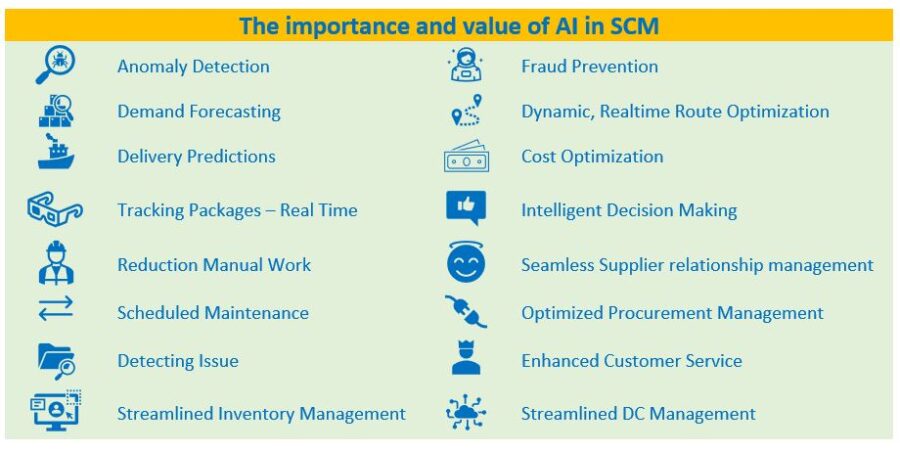

AI/ML use cases in the supply chain help retailers, suppliers and distributors drive transformational changes that are so much needed today in the face of the pandemic. Machine Learning delivers unprecedented value to supply chain operations: from cost savings through reduced operational overhead and risk mitigation, to enhanced supply chain forecasting, speedy deliveries, and improved customer service, to name a few. McKinsey forecasts that the most significant benefits of machine learning will be in providing supply chain professionals with more significant insights into how supply chain performance can be enhanced, anticipating anomalies in logistics costs and performance before they occur. Machine learning is also providing insights into where automation can deliver the most significant scale advantages.

Some use cases of AI in SCM:

Predicting customer’s behaviour:

Customers are uncertain and act based on emotions. And yet, success in the supply chain depends on customer data and their behaviour. In order to predict customer behaviours, many spreadsheet-based methods were proposed, but with the rise of big data they turned out to be obsolete. The main reason that spreadsheet models fail at demand forecasting is that they’re not scalable for large-scale data. They bring forth the complexities and uncertainties in supply chain management that cannot be extracted, analyzed, and addressed through simple statistical methods such as moving averages or exponential smoothing. This inconsistent-order pattern can lead to miscommunication between your team and loss of productivity. Predictability of inconsistent-order volumes is a challenge for many companies. AI and ML give us a closer prediction of the inconsistent nature of customer behaviour much earlier at an optimal level during such situations.

Predictive capabilities are helping demand forecasting:

Demand forecasting is a field of predictive analysis where companies anticipate the demand for products and shipments throughout the supply chain, even under uncontrollable conditions. Conventional methods, as discussed earlier (spreadsheet models, statistical models, moving averages and exponential smoothing) are limited due to the large number of parameters influencing the demand in SC, which makes these methods too simple and extremely inaccurate. In this regard, the forecasts could only provide a partial understanding of demand variations in supply chains. In addition, the unexplained demand variations could be simply considered statistical noise, this is what makes them non-linear in nature. Thus, conventional or simple models fail to map important and non-linear features. Luckily, machine learning provides algorithms that can map important and non-linear features, and reduce them into variables that can help to understand the past, accurately predict future events, help to improve decision-making processes about cash flow, risk assessment, capacity planning and workforce planning, and meet customer demands.

Some of the AI-powered demand forecasting tools available in the market:

- Capsule

- COLIBRI

- ClosePlan

- Effectmanager

- FutureMargin

Logistics & Transportation

ML helps understand where a package is in the entire logistics cycle. It allows supply chain professionals to track the location of goods during transportation. Also, it provides visibility into the conditions under which the package is being transported. With the help of sensors, retailers can monitor such parameters as humidity, vibration, temperature, etc. Besides, ML helps with real-time route optimization. It tracks weather and road conditions and gives recommendations on how to optimize the route and reduce driving time. This way, trucks can be diverted at any time on their way when a more cost-effective route is possible.

Avoiding charge-back risks

As mentioned earlier, customers are emotional. They might rethink buying if delivery is delayed. Or purchase a product and later ask for a refund. This eventually leads to penalties which may include shipping charges, taxes and other expenses. With integrated AI like the one Amazon uses, companies can analyse data to find the nearest distribution centre and reduce delivery time. Such systems can analyse the cause of delay, and the cause of failure, like disputes between partners or a catastrophe linked to bad weather.

Smart warehouses are more efficient

A smart warehouse is a fully automated facility where most work is done through autonomous robots or software. In the process, complex tasks are made simple, and operations become more cost-effective. Alibaba and Amazon have transformed their warehouses into a utopia of efficiency through the use of automation.

Production

With ML, it is possible to identify quality issues in line production at the early stages. For instance, with the help of computer vision, manufacturers can check if the final look of the products corresponds to the required quality level. If the products have some defects, it becomes easy to detect them before they reach the customers. One of the other widespread use cases of machine learning in the supply chain is predictive maintenance of the equipment. ML ensures reactive and preventative maintenance of equipment based on real-time asset data rather than a predefined calendar. By improving asset maintenance, supply chain professionals can significantly decrease maintenance costs. Also, ML helps to reduce the number of no-fault-found (NFF) cases. NFF is a unit that is removed from service following a complaint of the perceived fault of the equipment. If there is no anomaly detected, the unit is returned to service with no repair performed. The lower the number of such incidents is, the more efficient the manufacturing process gets.

Necessary algorithms, tools and frameworks

Convolution Neural Networks

Convolution Neural Networks (CNNs) are a type of algorithm that usually deals with image recognition, but it turns out that CNN’s are also extremely useful for forecasting. CNN’s are best known for extracting useful patterns and features from a dataset. This makes CNN very reliable for solving classification and regression problems.

Image Classification

Image classification is used to recognise the category of a given image. It’s quite handy in the supply chain, as it can classify different products in an instance, and separate them accordingly.

Object Detection

Object detection will help you to identify different objects instantly. In SCM, you come across a lot of products at the same time. Separating these products manually is very expensive and time-consuming. Object detection can help you to identify objects and categorize them quickly (making image classification much more precise) without any human interference.

Image Segmentation

Image segmentation is another algorithm that uses CNN to create a pixel-wise mask around the object itself, thus understanding the dimension of the object.

Autonomous mobile robots

Autonomous mobile robots use CNN to identify routes and navigate to assigned areas in the warehouse. These types of automated robots reduce errors in warehouse management, and they also reduce human involvement in the warehouse, which eventually reduces the risk of accidents. These robots use image classification, object detection and image segmentation to navigate across the warehouse, find the appropriate assigned designation for the object and know the dimension of the object, as well to avoid obstacles along the way.

Nature Language Processing (NLP)

Sentiment Analysis – every company needs feedback from the customer, this usually comes from the review section for each product. Going through each and every review manually and assigning to good, bad and anything in between can be a tedious job. Through sentiment analysis, companies can separate good and bad products based on the review and the ratings the customer provides. This helps to improve the user experience.

Chatbots – chatbots are another way to improve user experience. Customers can talk to a robot about issues or feedback they have, and NLP is what helps the robots understand them.

Deep Reinforcement Learning

The supply chain has a lot of components right with managing inputs from raw materials, to manufacturing, warehousing, and distribution to customers. Companies have to do their best to carry out these tasks efficiently and optimally while keeping the cost as low as possible. Optimization is the key. A lot of time and effort has been put into building effective supply chain optimization models, but due to their size and complexity, they can be difficult to build and manage. With advances in machine learning, particularly reinforcement learning, we can train a machine learning model to make these decisions for us, and in many cases, do so better than traditional approaches.

Time Series analysis

Matplotlib is one of the most widely used visualization libraries, for creating charts and plots, in the python community. It has a lot of functions, each beneficial to its own needs. In time series analysis, matplotlib offers a few major functions that are very handy. They are:

- Line Plots.

- Histograms and Density Plots.

- Box and Whisker Plots.

- Heat Maps.

- Lag Plots or Scatter Plots.

- Autocorrelation Plots.

Seaborn is another tool that is widely used for visualisation because of the colour palette and the interactions it provides through various shades and designs.

Plotly provides an additional function that the above libraries do not. It has a live interactive design with various functions like select, zoom in and out, etc.

Demand forecasting

ARIMA stands for AutoRegressive Integrated Moving Average. It is a class of models used to understand different standard temporal structures in time series data. ARIMA is very popularly used for time series analysis, including demand forecasting.

Clustering

Sklearn provides a lot of different functions to cluster your data. One of the most frequently used clustering algorithms is K-means. With k-means, a set of N data points are grouped into K clusters with the mean of each cluster becoming its identifying location.

Computer Vision

PyTorch is a scientific computing framework with wide support for machine learning algorithms. The Lua-based scripting language provides a wide range of algorithms for deep learning and uses the scripting language LuaJIT, and an underlying C implementation. It is easy to implement and work with. You can create your own custom CNN model or you can apply transfer learning as well. Pytorch has a wide and active community, helping and supporting fellow coders through its forum.

Tensorflow or TF is developed by Google. It provides good education support from the Google machine learning community and it is used to build simple and complex neural networks. Similar to PyTorch, TensorFlow provides a wide range of mathematical algorithms to build a neural network from scratch. Tensorflow also has Keras, which is a deep learning framework. It is one of the most widely used deep learning frameworks. Keras is simple and easy compared to both PyTorch and TensorFlow.

OpenCV is a vision library that is used to analyse and manipulate both images and videos. Mostly used for real-time applications. It is compatible with both PyTorch and TensorFlow.

Two use cases where AI is implemented in SCM

Amazon Intelligent Revenue and Supply Chain (IRAS) Management:

One of the global leading IT organizations developed integrates insights and findings generated by ML and AI models into its business and technology ecosystem for Amazon SCM. Its purpose is to improve the overall supply chain management system. It also takes care of the optimization of the forecasting and various other models, making sure that the whole system is optimal and cost-efficient.

Rolls Royce redefines safety measures to transport its cargo with AI:

Rolls Royce, the legendary British auto producer, cooperated with Intel to plan a clever AI framework that can make business transport quicker and more secure. They guarantee that this innovation will have the capacities to oversee route, hindrance location and correspondences, fostering another arrangement of independent ships autonomously. In a statement, they said: “This collaboration can help us to support ship owners in the automation of their navigation and operations, reducing the opportunity for human error and allowing crews to focus on more valuable tasks.” – Rolls Royce